Choose Your Design And Length

View allWhy You Need DIY Customs Rock Sliders!

-

❌ Don't be this guy!

❌ Big repair bill: It gets expensive real quick—often costs more than sliders.

❌ Water gets in → rust & sticky doors: Cracks let water/dust in, so rust starts and doors may not close right.

❌ Body hits rocks/logs: Without sliders you get stuck and scrape/bend the body; side steps can fold.

❌ Your mates will tease you: They’ll say you tried to save a few bucks without sliders. 😅 -

❌ Or this guy!

💸 Expensive to fix: Rocker/sill repairs need cutting, welding, and repainting—can run into the thousands, often more than a set of sliders.

🚪 Door problems: Bent sills knock doors out of alignment so they rub, stick, or don’t seal properly.

🌧️ Rust & leaks: Cracked paint lets in water and dust; rust starts inside the sill and spreads.

⏱️ Downtime & lower resale: Your rig’s off the road for repairs, and visible sill damage scares off buyers. -

✅ Do it the right way first!

✅ Stops dents to sills & door bottoms

✅ Slides over obstacles (no panel crushing)

✅ Tough step for kids, roof-rack & tent access

✅ Stronger than side steps — chassis-mounted, impact-ready

✅ Saves money vs panel and sill repair

✅ Keeps doors working; protects resale value

✅ DIY-friendly options, including weld-together kits made from Aussie steel

Collections

-

Universal Ladder Racks

Ladder racks suited to aluminium and flat bed trays

Let customers speak for us

from 105 reviews

Great product and service and value for money

Fits great works well

excellent product works perfectly

Great quality very fast postage

Ladder rack is what I needed, easy to fix, all questions answered and prompt delivery.

Great stuff

This kit made it fairly strait forwards and easy to make up a custom slider set for my 60 series

Quick turnaround time, makes the job easier to weld. Would recommend 10/10

Excellent product. I cut mine from 950mm to 780 mm. Installed with ease. Now my San Hima roof top tent is the same height as roof. Zero affect on wild drag.

Would highly recommend the universal ladder rack.

Product arrived quickly and as described. the only thing I had to purchase was done threaded Rod for the mounts

Ladder rack was very good. It works as described and is doing the job as intended.

Good stuff mate 10/10

Great product and customer service was excellent. Would use them again.

Great fit to my hilux

Makes the job easy and saves time

Rock Slider Kit Questions

1. Is this ready-made or a kit ?

It’s a DIY kit. The parts come loose and need welding—it doesn’t come welded or painted. If you’ve got a 4WD and want to get into light customisation and fabrication, this is the perfect first project for you.

2. What are rock sliders ?

Rock sliders are thick steel rails that sit under your doors—like armour for your 4WD.

- They take the hit so your sills (the thin metal under the doors) don’t get crushed.

- They help your car slide over rocks, ruts and stumps instead of getting stuck.

- Many styles double as a step (kick-out = extra step room).

- Not for towing or recovery—they’re for protection.

If a rock hits the side, the slider hits first—not your bodywork.

3. What do I get, and what are they made from ?

Steel rails and tubes with end caps, ready to weld. Brackets are optional—add the Universal Mounting Kit (brackets, gussets, bolts, washers, nuts). Parts are heavy-duty mild steel and usually supplied raw so you can paint or coat them.

4. Will they fit my 4WD, and what length should I choose ?

If your 4WD is listed on our site: choose that option—size is already set.

If your 4WD isn’t listed: measure the straight sill length you want to protect (front to back), then round down to the nearest size. Example: 1840 mm → 1800 mm.

5. Do I need special tools or skills ?

No tube bender or notcher needed—the bends and notches are done.

You do need to weld (a basic MIG is fine) and have normal fab tools like clamps and a grinder.

6. Can I stand on them ?

Yes. Although you can stand on all of the designs, the Kick-out styles also give extra step room and help push the body away from obstacles.

7. Can I jack the car from the sliders ?

Yes you sure can as They’re tough, but safe jacking depends on your welds and how you mount them. If you’re not sure, play it safe.

many customers have had no complaints with jacking their vehicle from our DIY rock sliders

8. How hard is the install, and do you have instructions ?

We don’t include printed instructions because every vehicle is different. Most people follow YouTube build/install videos—just search “DIY Customs rock sliders” in youtube.

If you’re handy with basic welding and measuring, plan about a day in the shed. If you get stuck, message or call us and we’ll point you to good videos and tips.

9. How is shipping handled ?

Shipping is shown at checkout for your address. We pack parts flat to keep freight costs down, and we’ve negotiated sharp rates

Our freight is some of the cheapest in the industry.

10. Can your products be delivered straight to my door ?

- Yes. Our rock sliders (and other kits) can be delivered to your home—not just depots or business addresses.

- Australia-wide residential delivery

- No forklift needed

- Remote or tricky access? We’ll organise a safe drop-off with you

- We keep costs low with flat-packed freight and some of the cheapest rates in the industry

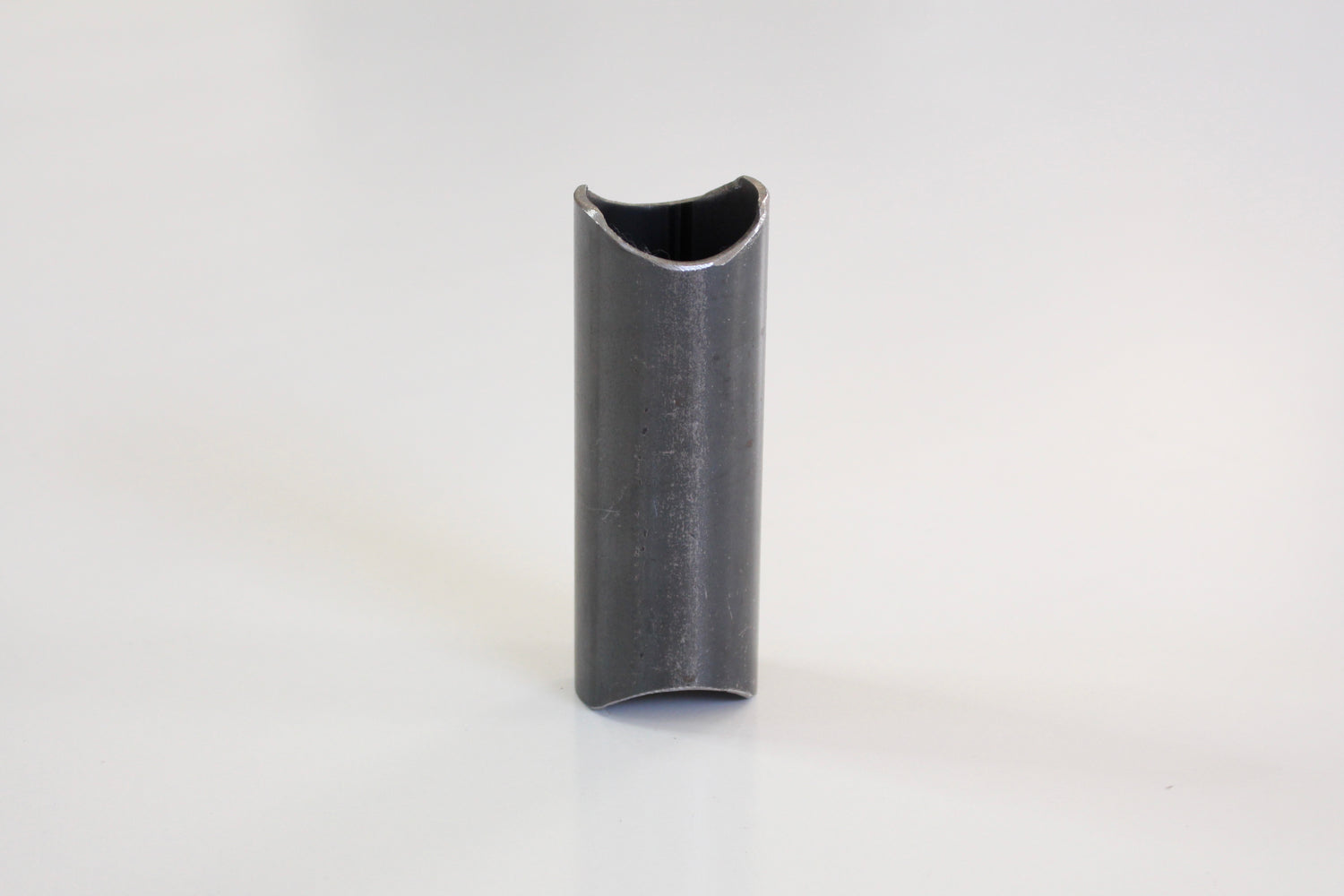

90 Degree Notches

Top Quality And Perfectly Fitting Parts That Go Into Your Rock Slider Kits To Make Welding A Breeze

41 Degree Notches

Perfect Fitment Of All Angled Notched Parts

Ready To Weld

Each Part Is Cleaned Extensively To Make Sure There Is No Burrs Or Sharp Edges So It Is Ready For Welding Straight Out Of The Box

Let customers speak for us

from 105 reviews

Great product and service and value for money

Fits great works well

excellent product works perfectly

Great quality very fast postage

Ladder rack is what I needed, easy to fix, all questions answered and prompt delivery.

Great stuff

This kit made it fairly strait forwards and easy to make up a custom slider set for my 60 series

Quick turnaround time, makes the job easier to weld. Would recommend 10/10

Excellent product. I cut mine from 950mm to 780 mm. Installed with ease. Now my San Hima roof top tent is the same height as roof. Zero affect on wild drag.

Would highly recommend the universal ladder rack.

Product arrived quickly and as described. the only thing I had to purchase was done threaded Rod for the mounts

Ladder rack was very good. It works as described and is doing the job as intended.

Good stuff mate 10/10

Great product and customer service was excellent. Would use them again.

Great fit to my hilux

Makes the job easy and saves time